On December 7th, Halo Space, a global space tourism company, successfully completed the first test flight of its dummy capsule. The flight lasted 4 hours, and the unmanned prototype reached 37 kilometers up in the stratosphere and landed back on the ground with great precision and safety.

News

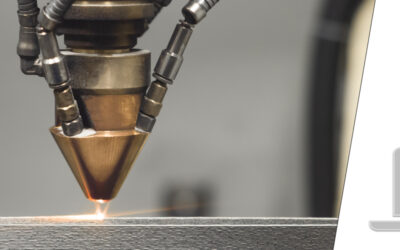

CT successfully moves forward on a design methodology for large aerospace components through the REMEDI project.

CT is successfully moving ahead on the REMEDI project that it has led for the last three years, as part of the Smart Eureka Advanced Manufacturing call for projects. The project aims to define an optimal, efficient and lightweight design methodology to manufacture medium/large components, taking full advantage of the capabilities of DED (Directed-energy Deposition) additive manufacturing technologies using laser technology and the addition of metal powder.

CT makes the leap into space tourism.

CT has decided to take a new step in its innovation and diversification strategy. The company has become the engineering service provider of the Spanish space tourism company HALO Space.

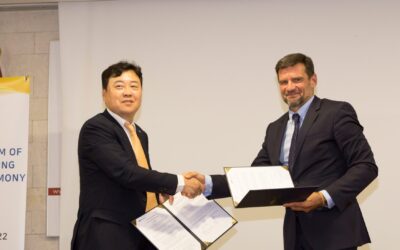

CT signs an agreement with the Korea Electronics Technology Institute to boost cooperation in R&D.

CT has signed a cooperation agreement with the Korea Electronics Technology Institute (KETI), world leader in business research and development, to promote R&D in new technology and sustainability.

CT to research smart automated fabrication 4.0 for large composite parts for the naval sector.

A ground-breaking proposal that combines sustainability and Industry 4.0 in the fabrication of naval components.

CT leads the EDF funded KOIOS 10 million euro defence industrial cooperation Artificial Intelligence project.

The KOIOS project proposal, led by CT, has been selected by the European Commission to develop Artificial Intelligence (AI) applications for the defence sector within the European Defence Fund (EDF) programme. CT leads a consortium of 14 entities (companies, universities, technology centres and European SMEs) including the Barcelona Supercomputing Center – National Supercomputing Center (BSC-CNS) and NTT DATA, in a 10 million euro AI focused defence industrial cooperation project.

CT highlights its commitment to applied engineering solutions based on Industry 4.0 at Navalia.

At this year’s Navalia trade show, CT presented its engineering solutions and proposals for the digitalization of the product life-cycle that are applicable to all sectors, systems, equipment and components. During the three days of the event, the CT stand was a meeting point for visitors and customers who were able to try out immersive virtual reality and augmented reality solutions for maintaining ships during their useful life.

CT expands its 4.0 solutions portfolio with the acquisition of Infodream, a Manufacturing Execution System software development company.

CT acquires Infodream, an international company based in France, specialized in Manufacturing Execution System (MES) software development for Industry 4.0.

With this operation, CT adds to its digital transformation solutions, a full MES suite, offering very powerful modules as statistical process monitoring or operator guidance in the manufacturing cell.

CT, selected as a System Engineering Supplier in Airbus Operations.

CT consolidates its position as a major partner of Airbus following its selection in a recent call for tender process for System Engineering activities (JECO). This is in addition to CT’s selection, once again, as a Global Preferred Engineering Supplier under Airbus’ EMES3 (Engineering, Manufacturing Engineering and Services Strategic Supplier) program, which has placed it among Airbus’ top suppliers worldwide.

CT advances in the development of ADDHOC, a solution for the industrial manufacturing of highly customized short series based on additive technologies.

CT, from its delegation in Bilbao, leads the Basque R&D initiative ADDHOC, which will develop a new family of digital tools, CAx, to introduce new metallic additive technologies in industrial sectors with mechanical, short series and highly customized requirements.

The project belongs to the Business R&D Support Aid Program – Hazitek, an action co-financed by the Basque Government and the European Union through the 2021-2027 European Regional Development Fund (ERDF).

CT collaborates with the Xunta de Galicia on Vocational Training.

Last Wednesday, 9 February, in the Ciudad de la Cultura in Santiago de Compostela, the Xunta de Galicia held an event to acknowledge the commitment of different Galician companies to improve and promote Vocational Training in the community. The event was attended by...

CT and Curium form a consortium to develop IoT & Industry 4.0 applications.

Curium & The CT Engineering Group form a consortium to collaborate in the areas of IoT and Industry 4.0 across Europe and Asia.